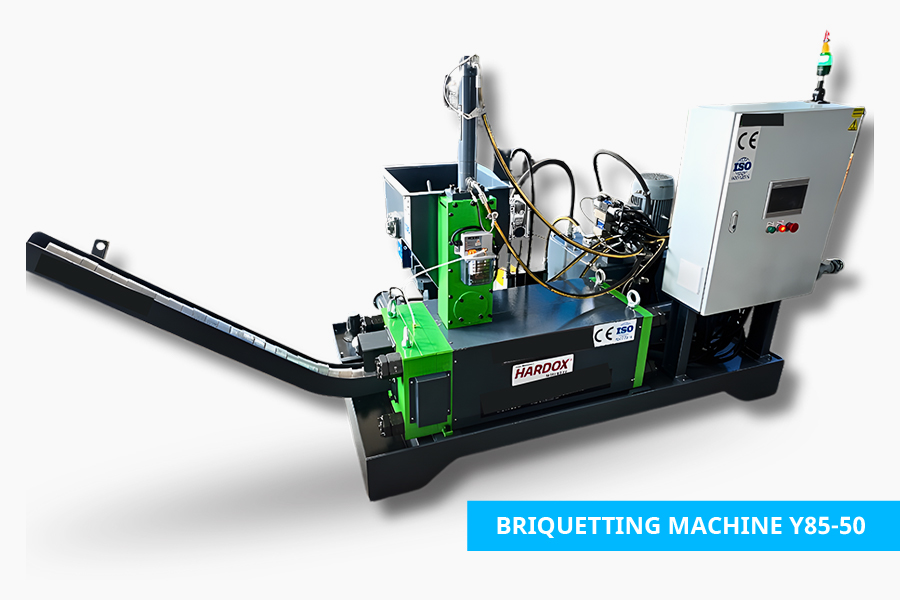

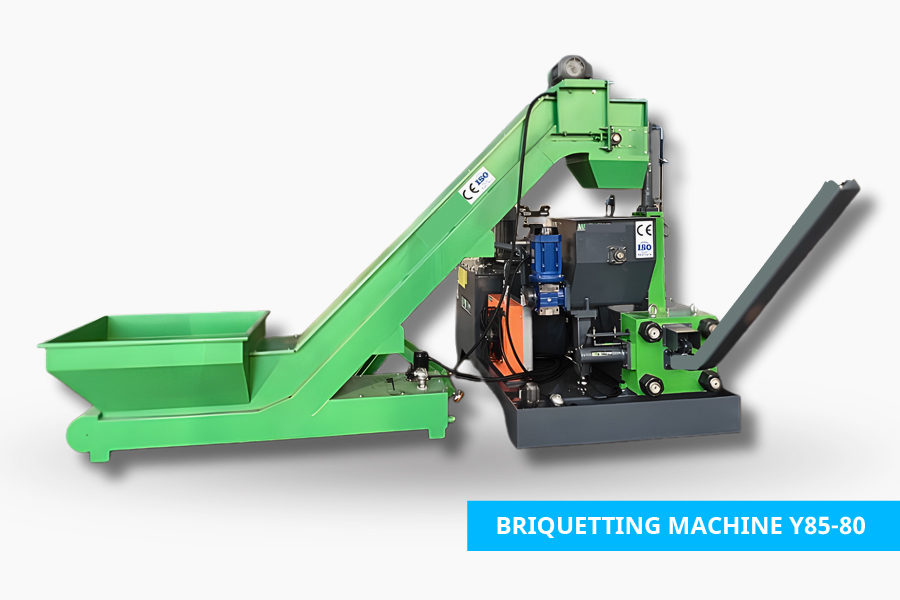

“SMALL” BRIQUETTING MACHINE

Small briquetting machines are ideal for reducing the volume of metal chips directly at the discharge point of machine tools. They compress short chips, transforming them into compact briquettes with a density that can reach 1.8–2 kg/dm³ for aluminium and 5.5–6.5 kg/dm³ for steel. During the process, the coolant contained in the chips is automatically recovered and recirculated. They are not suitable for processing monolithic bodies or filamentous chips.

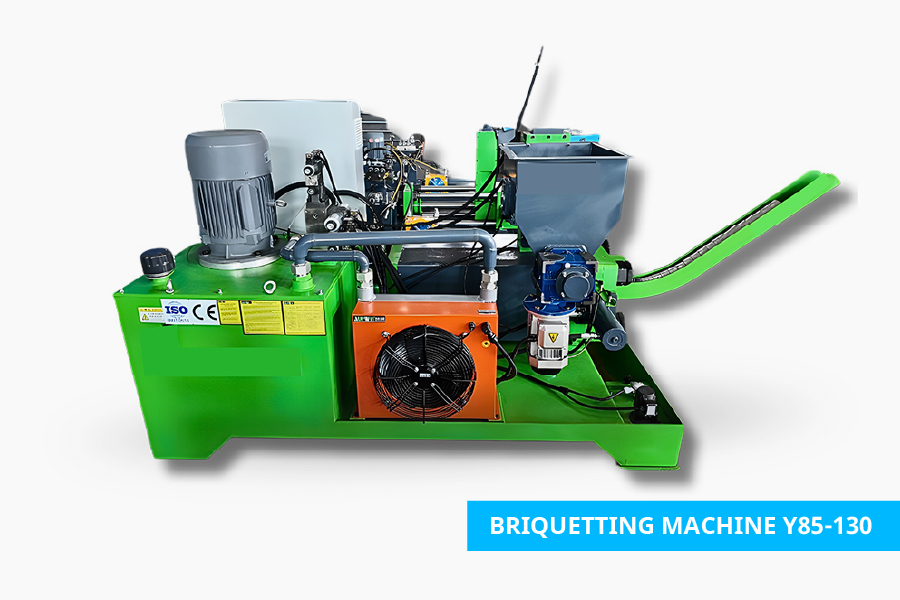

“HARD” BRIQUETTING MACHINE

Hard briquetting machines are capable of receiving the entire production of turning and milling departments with centralised management of metal chips. They press short chips to produce high-density briquettes with a density that can reach 2–2.2 kg/dm³ for aluminium and 6.5–7 kg/dm³ for steel. During the process, the coolant contained in the chips is automatically recovered and recirculated. They do not accept monolithic bodies or filamentous chips and, in the presence of long chips, they are often combined with a twin-shaft shredder.