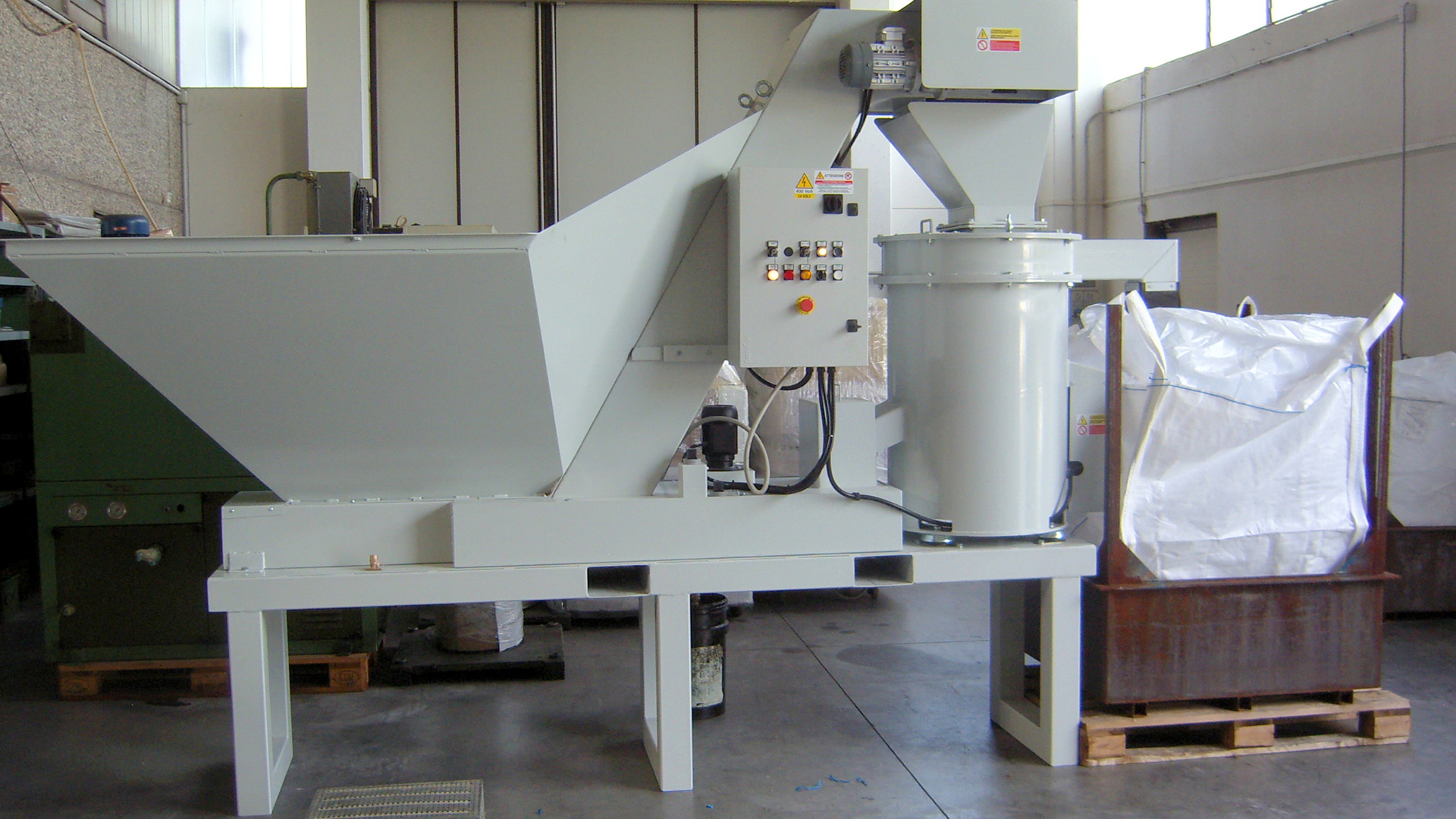

The spinning system named "Minisystem" is a compact system for the metal swarf spinning.

Benefits:

- High coolant recovery (residual moisture <2%)

- Modular and placed on a skid

- Compact

The Minisystem® is composed of:

- A conveyor feeds the centrifuge. The conveyor is equipped with a tank, pump and electric levels for sending the coolant

- A bar end separator

- A vertical centrifuge

- A skid to handle the system

- Electrical panel for the system management

The system is modular and can be integrated with:

- Skiphoist,

- Crusher when the swarf is stringy,

- Swarf conveyor to the container or silo

- Filtration system for coolant

The throughput of the system varies according to the treated material:

- 180-200 kg / h * for short brass swarf, with density 1 kg = 1dm3

- 160-180 kg / h * for short steel swarf, with density 1 kg = 1dm3

- 70-80 kg / h * for short aluminum swarf

* Indicative data